Amandus D. Moyer

Amandus D. Moyer

Posted on Wednesday, January 10, 2018

Categories:

Trucks & Delivery

|

History

The Commonwealth of Pennsylvania is rich in a variety of

natural resources which have most certainly played a key role in the growth and

development of the state and of the world over the decades. In fact, over the

past two centuries, Pennsylvania has been a world leader the production of

steel, coal, coke, cement and lumber.

When Pennsylvania was settled, it’s believed that her

grounds were 90% covered by forest. White pine, eastern hemlock and assorted

hardwoods grew abundantly and were harvested in large numbers to support the

population spread of settlers westward off of the east coast. Water-powered saw

mills supplied the massive appetite for new lumber in construction projects

across the region starting in the 1800s.

In the 1860s Pennsylvania led the nation in lumber

production, but by 1900 it had dropped to fourth. During that period,

Williamsport's log boom on the Susquehanna had been the world's largest lumber

pile.

By the 1920s, a majority of the old-growth forests in

Pennsylvania had been depleted, prompting the Commonwealth to purchase

thousands of acres of land from lumber companies and begin to regulate and

reforest the landscape. This gave birth

to the modern conservation movement and continues to influence modern-day

forestation practices in the industry.

So now that we know all is well with the Pennsylvania

forests and that her hardwoods are, once again, plentiful and in demand

worldwide, let’s take a look at how lumber delivery has evolved over the

centuries.

1800s Lumber Delivery

By the 1790s, New England was exporting 36 million

board feet of pine boards and 300 ship masts annually. As the availability of

adequate trees diminished in the far Northeast, Pennsylvania’s tall and true

white pine and hemlock trees were in high demand for these masts. Movement of

lumber from one point to the next on land was accomplished by horse-drawn

wagons and via the railroad after 1830.

Pennsylvania’s large and numerous rivers provided for

massive floating log rafts to move thousands of trees to the water-powered sawmills. Sawn lumber was then loaded on barges to

continue down river, and on carriages and rail cars for transport over land.

Early 1900s Lumber

Delivery

In Pennsylvania and the rest of the nation, the industrial

revolution rode on American rails.

Trains carried coal and lumber to consumers quickly and cheaply. The invention

and popular rise of the automobile in the early 1900s rapidly changed the way

Americans moved themselves and their cargo. Trucks of the era mostly used two-cylinder internal-combustion

engines and had a carrying capacity of 3,300 to 4,400 pounds. In 1904, 700

heavy trucks were built in the United States, 1000 in 1907, 6000 in 1910, and

25000 in 1914.

Lumber delivery even played a part in the prohibition era with some very creative disguises to smuggle alcohol.

Hydraulic Hoists in

Lumber Delivery

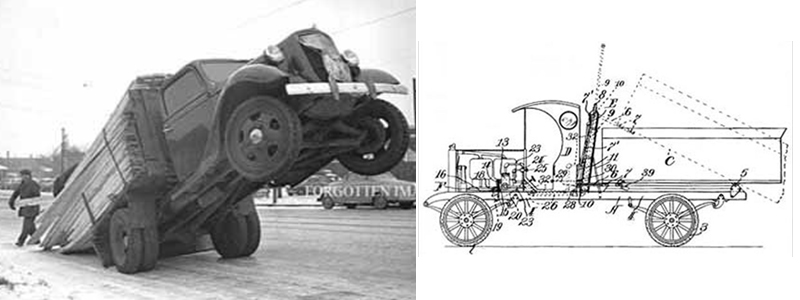

Prior to the invention of the hydraulic lift on trucks, dump

beds were available but required a brutal 30-minute process of hand cranking

the bed high enough to cause the cargo to slide off of the bed of the truck. The

invention of the hydraulic hoist on truck dump beds by Gar Wood around 1915

changed the delivery industry dramatically. Well after the invention but before

trucks were widely equipped with hydraulic dump beds, creative lumber truck drivers

would travel in reverse at high speed and slam on the brakes, shifting the load

backward and raising the entire front of the truck off of the ground. They

would then drive out from underneath the partially-dumped load, slamming the

front of the truck back to the ground when the load released.

Post World War II in

Lumber Delivery

World War II played a large part in inspiring American

mechanics and machinists to new heights. Post-war inspirations gave us the Harley-Davidson

Sportster in 1957 along with the ’57 Chevy. Many post-war inspirations in trucks

also arose. Soldiers returning from war had learned their vehicles inside and

out and dreamed of all that they could accomplish back at home. Vehicles like

the Willys Jeep which played a huge role in winning the war, became the first

4-wheel drive vehicle to be manufactured in six-figure numbers. Additional multi-axle and higher clearance post-war inspiration was introduced to the domestic delivery truck which continued to grow in size, capacity.. and demand.

Interstate Highways in

Lumber Delivery

The Federal-Aid Highway Act of 1956 authorized

the construction of the Interstate Highway System, an interconnected

network of controlled-access freeways that allowed larger trucks to travel at

higher speeds through rural and urban areas. This act also authorized the first

federal maximum gross vehicle weight limits for trucks, set at 73,280 pounds.

The Federal-Aid Highway Amendments of 1974 established

a federal maximum gross vehicle weight of 80,000 pounds, and introduced a

sliding scale of truck weight-to-length ratios based on the bridge formula, but

did not establish a federal minimum weight limit. The decade

of the 70s saw the heyday of truck driving, and the dramatic rise in the

popularity of "trucker culture". Truck drivers were romanticized as

modern-day cowboys and outlaws, a stereotype that persists even today.

Big rigs littered the highways, carrying lumber and America’s

daily-growing cargo demands across the nation.

Modern Day Lumber

Delivery

By 2015 there were over 31.4 million trucks on America's

roads, hauling 10.5 billion short tons of freight annually, representing

nearly 70.1% of the total domestic tonnage shipped in the United States. Lumber delivery drivers now benefit

from tilt split flatbeds and multiple axles including a lift axle which can be raised or lowered as the operator needs, increasing their operating capacity. Added truck-mounted accessories including the knuckle boom crane and the

Moffitt forklift are also common. These features permit

drivers to do far more than just dump the load which can lead to damage of

property and materials depending on the circumstances. Cranes and forklifts provide the diversity to easily lift

and carefully place the load in areas where the truck cannot fit, including upward.

Rooftop delivery and delivery to floors above ground level are now a daily occurrence

without a second thought for the modern lumber delivery driver.

The modern-day railroad continues to play a key factor in getting

the timber to the lumberyard, shipping 24 million tons of lumber and wood products annually. Rail delivery enables Pennsylvania lumber buyers

to bring in loads totaling tens-of-thousands of board feet from mills in Canada

and the Pacific Northwest.

[Resources] Pennsylvania Lumber Museum, American Trucking Association, Philadelphia Reflections, Historic Building Materials & Methods, Statista, Wikipedia, Britanica, Popular Mechanics

Tagged:delivery, lumber, Pennsylvania, trucks, history, nostalgia